How come I’m so crusty these days? Could it be my nerves are frayed from everything happening at once? Naw, I’m used to that. It is lack of sleep from the new band and this project. And gems like having to throw out my bag of brown sugar when the ants found it. Everything in the tropics must be kept in a sealed canister. There is also the moisture/humidity thing to deal with. I get cranky unless I have a regimented amount of sleep every day. Have not been getting it.

Today’s electronics report has more to do with software than diodes and I extend an apology to ExpressPCB. The inability to place components except at right angles seems, in retrospect, not that big of a deal. However, since there was nothing inaccurate in my original comments, nothing changes. (This blog only changes when proven errors are pointed out. An honest opinion expressed some time in the past is rarely an error, Ken.)

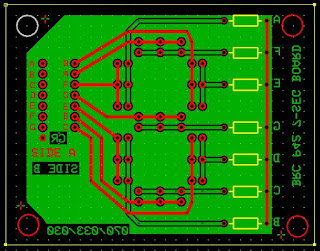

But let’s talk of the academic side of free thinking. Shown here is my design to prove that the wiring can be designed. However, ExpressPCB cannot render this circuit, only display it. That’s awesome because it is more confirmation that my idea is original. This app is given away by a company that wants to build the circuit board for you. Why is this so important to me? What difference does it make? Funny you should ask those very questions right when I have time to give the answers.

But let’s talk of the academic side of free thinking. Shown here is my design to prove that the wiring can be designed. However, ExpressPCB cannot render this circuit, only display it. That’s awesome because it is more confirmation that my idea is original. This app is given away by a company that wants to build the circuit board for you. Why is this so important to me? What difference does it make? Funny you should ask those very questions right when I have time to give the answers.What we’ve got here is one of those situations that constitute an excellent little test of your character, not mine. The side you take will be a revelation of whether this blog is the right blog for you. There are two ways to interpret my squabble with the design program. Here it is as a multiple choice question:

A. I’m such a lunkhead I can’t use a perfectly good CAD app.

B. My very first circuit was so advanced it tested their software to the limit.

Let’s examine a few facts. The way this evolved was not that I found software that didn’t have the feature I needed. That could happen to anyone. But nor did I find the feature was included where one could disable it and carry on. No, that is not the case either. What we have is software used by tens of thousands that outright blocks my attempts to design something new and different. Can’t be done, and that pretty much spells out the mentality of countless users who never questioned this commandment, not even once. You cannot have a wire with only one end.

So let’s take a vote. Fifty million engineers can’t be wrong. OMG, I’m a lunkhead! Does this mean I have to break up my working prototype to conform to the rules?

Later. I stayed in drinking ginger tea and learning “Sunny Afternoon”, the Kinks tune. Am I still on that? Yes, last day I learned the riffs. Now I have to memorize the song and it does have the usual verse-chorus pattern. The bass line has to be memorized start to finish and I’m oh, maybe half-way there. There’s some guy advertising the usual boards saying he wants to get into a band right away so he can make money and meet women. What? Well, okay. Yes, but I was fifteen, not thirty-five.

ADDENDUM

I made an extra pot of tea, ginger tea this time, and thought the etching (printed circuit board) problem through. I cannot use two-sided copper clad because the component leads must not touch the same layer. At this time, I do not have a workable solution. Oops, I’ve never defined copper clad. Don’t you hate it when authors do that? Copper clad is those sheets of plastic (phenol) that circuit boards are printed on. Before etching they look like this:

There are 4-layer plates, but these are a double-sided type that have more plates sandwiched between, one is positive, the other is negative. I would like to know how the connections are made. It can’t be an ordinary drill hole since there will be times when one simply has to pass through one plate to get to another. A fastener that works in this situation would make my life easier.

I spent hours trying to find ways to route traces on a sign layer, Euler style. In the end, no dice. I’ve learned to make the traces thicker and prettier. Thin traces cannot bend at angles greater than 45 degrees due to manufacturing restrictions. I will order both types of plates. Single and double side, plus 4-layer if I can find it. My existing equipment can only work with single-side, but might as well look ahead.

Part of the complexity is transferring the design to both sides of the copper. The method is to heat the ink with an ordinary iron until it sticks to the copper. This means a temperature of 200 Fahrenheit, another entity I have no way to measure. How do the two sides of the [opaque] design get aligned? Won’t the first side smear when I reheat the plate for the other side? Guess I’ll find out soon enough.

The very fact I’m discussing these points will tip the reader off that I’ve got enough of the CAD application figured out to the point I can create logical patterns. It was simple, I gave myself one day to get two months experience. While copper clad is more complicated than using a breadboard, I remember when breadboard layouts were enough to give me the jeebies.